Sono Check RRS, a new test dosimeter for monitoring the ultrasonic energy in ultrasonic cleaner used for reprocessing surgical instruments was successfully validated. When the ultrasonic cleaner is supplying sufficient energy and conditions are correct, Sono Check RRS will change color. Problems such as insufficient energy, overloading, water level, improper temperature and degassing will increase the time needed for the color change.

SonoCheck Validation Test

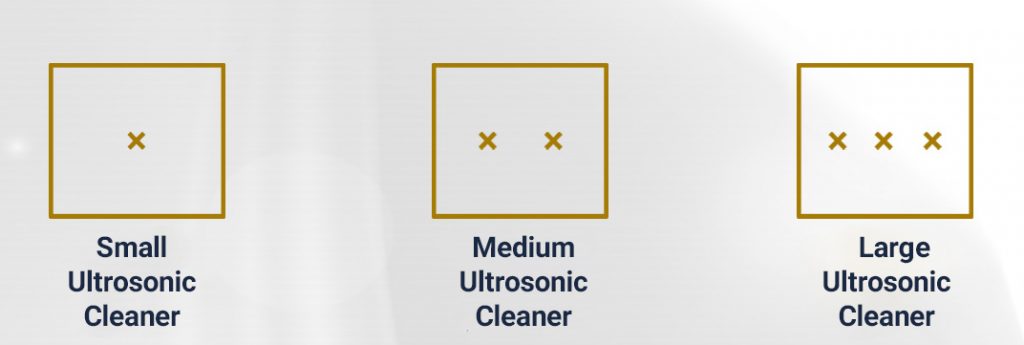

Place the Sono Check in an empty ultrasonic basket and place the basket in the ultrasonic cleaner.

Degas the bath and turn on the ultrasonic cleaner in accordance with the ultrasonic manufacturer’s instructions.

Check the color of the reagent, visually. SonoCheck will indicate sufficient ultrasonic energy levels for cavitation by a color change from blue- green to yellow caused by chemical reaction triggered by cavitation.

The Time required for the color change provides more information about the level of ultrasonic energy.

5- Finally, the results (temperature and color change time) should be recorded in the Sono Check log sheet.

SonoCheck Routine Test

Note

Storage

Store Sonocheck-box in the fridge (4-8 °C). Do not allow it to freeze and keep away from sunlight, high temperature, and chemical agents.

Shelf life

12 months after production. Pay attention to the expiration date on the packaging label.

Disposal

Sonocheck should be disposed of in a safety box container. because it contains glass.

Download Catalog

Please Check out file at the following link

Protein Test (Indicator of Monitoring the Washing Process) (RRS 14-41110)

Hemo test (Indicator of Monitoring the Washing Process) (RRS 14-42110)

Paper Sealer Device Test (RRS 14-81110)

Ink Sealer Device Test (RRS 14-81210)